Accelerate The Integration Of Two Depths

According to Dai Weihong, general manager of Jiangsu Southern Packaging, technological innovation has always been one of the development strategies of Southern Packaging Group. At present, the pace of market changes is accelerating, labor costs and raw material prices are rising. Only by improving the level of intelligent manufacturing equipment and accelerating the in-depth integration of informationization and industrialization can we improve the comprehensive competitiveness of sub-sectors.

In 2017, Jiangsu Nanfang Packaging Co., Ltd. introduced China’s first fully automatic high-speed rotary blow molding production line. The production line is customized according to the product process of the target project. Multiple subsystems are evaluated and integrated one by one. There are at least 5 countries. System suppliers participate in R&D and manufacturing, from technical evaluation, design, verification to commissioning and production for more than two years.

According to Dai Weihong, the production line is mainly divided into the following five subsystems:

1. Central feeding system: The raw materials in the four 60-ton stainless steel storage tanks can realize high-speed automatic weighing, proportioning and mixed transmission through the weighing station in Switzerland and the rationing and transmission station in Italy.

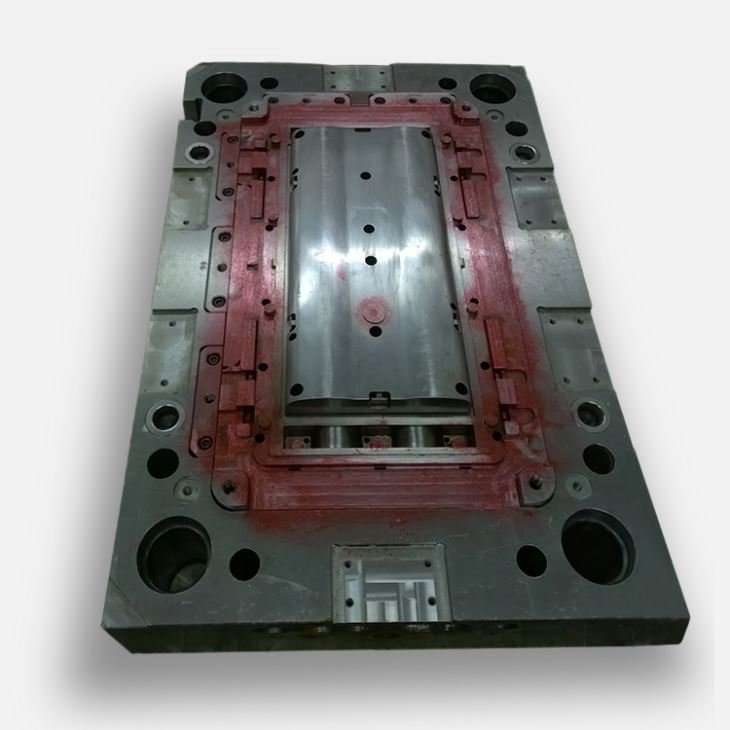

2. Rotating system: The system developed in the United States is equipped with high-precision molds from Canada. The daily production capacity of the target project can reach 1 million bottles, which is 15 times of the existing equipment capacity in the target project.

3. High-speed automatic detection system: Covers the full visual appearance detection consisting of 7 high-speed cameras in Germany, high-speed bottle measuring, leak detection in Spain, and metal detection in the United States. The detection speed accuracy is at the world’s leading level in the industry.

4. Spain’s fully automatic packaging system: to achieve fully automated operation of sorting bottles, film packaging, stacking.

5. Intelligent warehousing and logistics system: realize intelligent logistics and system data entry of AGV robots in the factory.

The integration operation of the above subsystems is technically difficult and difficult to implement in the global industry leading level. However, after smooth operation, its production capacity, efficiency, quality stability and automation are greatly improved, while energy consumption costs, labor costs and packaging costs are greatly increased. decline.

“The production line of the production line has filled the blank of the rotary blowing technology in the domestic plastic bottle blowing field.” Dai Weihong stressed. At present, the line is operating normally, and has successfully passed the customer’s verification and trial production acceptance, and is gradually expanding the mass production to replace the original similar products produced by customers.